3D Printing Plastics Market Size and Growth Analysis

The 3D Printing Plastics Market report by MarketDigits provides a comprehensive analysis of the industry, covering key segments such as type (Photopolymers, ABS, PLA, Polyamide, and others), form (Powder, Filament, Liquid), application (Prototyping, Manufacturing), and end-use industries (Healthcare, Aerospace & Defense, Automotive, Electrical & Electronics, and others).

The report highlights the partner and customer ecosystem, including product services, propositions, and key features, while offering insights into competitive indices and regional footprints. The forecast period from 2024 to 2032 offers a detailed overview of market trends, growth opportunities, and strategic dynamics across different regions.

The 3D printing plastics market has witnessed a substantial surge in recent years, driven by innovations in additive manufacturing and increasing demand for advanced materials. With diverse applications across various industries, such as healthcare, aerospace, automotive, and electronics, this market is poised for significant growth.

The 3D Printing Plastics Market was valued at USD 2.1 billion in 2022 and is expected to reach USD 11.4 billion by 2030, with a compound annual growth rate (CAGR) of 23.5% during the forecast period from 2024 to 2032.

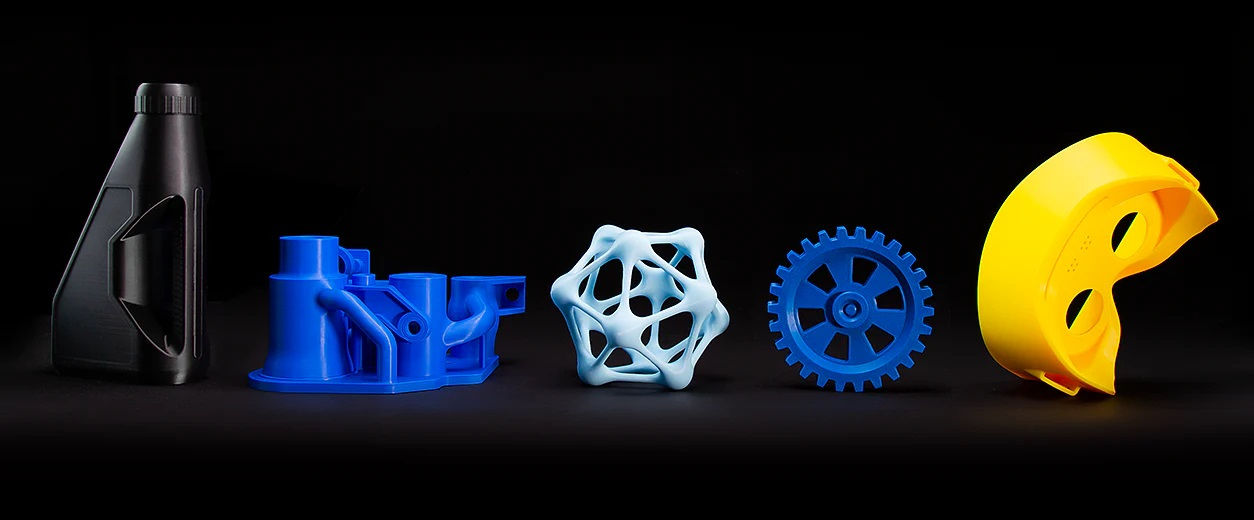

3D printing plastics, also known as additive manufacturing plastics, are critical materials used in the 3D printing process to create prototypes, parts, and products. These plastics come in various forms, including powder, filament, and liquid, and are used in multiple applications such as prototyping, manufacturing, and production across several key industries. The primary types of 3D printing plastics include photopolymers, ABS, PLA, polyamide, and others.

The market growth is driven by the increasing adoption of 3D printing technologies for industrial production, especially in sectors like healthcare, aerospace, automotive, and electrical & electronics. These industries benefit from the customization, cost-effectiveness, and efficiency offered by 3D printing.

Get the Sample Research Report Copy on 3D Printing Plastics Market: https://www.marketdigits.com/request/sample/316

Latest and Evolving Trends in the 3D Printing Plastics Market

1. Advancements in High-Performance Materials

A major trend in the 3D printing plastics market is the development of high-performance materials such as PEEK (Polyetheretherketone) and PEI (Polyetherimide). These advanced plastics are becoming increasingly popular due to their superior mechanical properties, high heat resistance, and chemical stability. As a result, industries like aerospace, automotive, and medical devices are leveraging these materials for the production of more durable, lightweight, and complex components.

The high-performance plastic segment of the market is expected to grow significantly. It is projected to expand from USD 152.52 million in 2024 to USD 852.51 million in 2032, with a CAGR of 24.0%. This growth is driven by the demand for stronger, more reliable materials in critical applications such as aerospace engine parts, medical implants, and industrial components.

2. Sustainability Initiatives in 3D Printing

Sustainability is becoming a key focus in the 3D printing industry, as manufacturers look for ways to reduce their environmental footprint. One notable development in this area is the recycling of plastic waste into usable 3D printing materials. For instance, Cornish start-up Fishy Filaments has pioneered the process of turning discarded fishing nets into engineering-grade nylon suitable for 3D printing. This innovative approach not only helps tackle plastic pollution but also provides manufacturers with a sustainable and eco-friendly material option.

As businesses and consumers alike become more conscious of environmental issues, the adoption of recycled and biodegradable plastics in 3D printing is expected to increase. The integration of sustainability into the manufacturing process is likely to play a crucial role in the future growth of the industry.

3. Integration of 3D Printing into Consumer Products

While large companies like Nike and Adidas have been cautious about incorporating 3D printing into their consumer product lines, smaller companies and start-ups are embracing this technology with impressive results. Companies such as Zellerfeld and Hilos have taken the lead in producing and shipping 3D-printed sneakers, offering fully customizable products that can be tailored to individual consumer needs.

This trend highlights the growing potential of 3D printing in consumer goods, particularly in the fashion and footwear industries. With 3D printing enabling on-demand production and personalization, it is likely that more companies will explore this technology to enhance product offerings and meet the rising demand for customized goods.

4. Regional Growth Dynamics in 3D Printing Plastics

The global 3D printing plastics market is experiencing diverse growth dynamics across different regions. While North America and Europe continue to lead in terms of market share, the Asia Pacific region is expected to exhibit the highest growth rate in the coming years. Rapid industrialization, coupled with increasing investments in 3D printing technologies in countries like China, India, and Japan, is driving this growth.

As industries in Asia continue to embrace advanced manufacturing technologies, the demand for high-quality 3D printing plastics is expected to increase, further contributing to the market's expansion.

Latest Trends in PETG, Polycarbonate, and Recycled 3D Printing Filaments

The 3D printing industry continues to evolve with advancements in materials such as PETG and polycarbonate filaments, alongside a growing trend toward sustainability through recycled 3D printing filaments. These materials are gaining significant traction in various sectors, from prototyping to production of end-use components, due to their unique properties and benefits.

PETG, or Polyethylene Terephthalate Glycol-modified, is an increasingly popular thermoplastic used in 3D printing. Known for its strong balance of flexibility, strength, and chemical resistance, PETG is suitable for a wide range of applications. This filament is favored for its ease of use, good clarity, and superior adhesion properties. Available in different colors and diameters, PETG filaments are commonly priced between $20 and $55 per kilogram, depending on the brand and specifications. The material’s versatility makes it a go-to choice for applications that require a balance between durability and ease of handling.

Polycarbonate (PC) filaments, on the other hand, are known for their exceptional strength, impact resistance, and heat resistance, making them ideal for demanding applications. The high temperature resistance of polycarbonate allows it to be used in industries that require materials capable of withstanding extreme conditions, such as automotive, aerospace, and electronics. Polycarbonate filaments are available in a variety of colors and are widely used for applications such as durable parts, prototypes, and high-performance components. However, polycarbonate requires careful control during 3D printing due to its high extrusion temperature, which typically ranges between 270°C and 310°C. Using a heated bed is critical to prevent warping and ensure good adhesion during the printing process.

Polycarbonate 3D printing services are becoming increasingly popular for those who may not have access to high-temperature 3D printers. These services cater to various industries by offering a means to create durable and heat-resistant parts without the need for in-house equipment. Companies providing polycarbonate 3D printing services offer high-quality prototyping and production of end-use components, helping businesses and individuals meet the growing demand for polycarbonate’s unique properties.

Sustainability is a significant focus within the 3D printing industry, and the trend towards recycled 3D printer filaments is gaining momentum. Companies are increasingly turning to recycled plastics to reduce waste and offer environmentally friendly alternatives to traditional filaments. For instance, Polymaker has pioneered the production of recycled filaments, such as PC-r, which is made from recycled polycarbonate sourced from 19-liter water bottles. This initiative contributes to sustainability efforts while providing high-quality materials for 3D printing. As the industry continues to emphasize sustainability, the adoption of recycled filaments is expected to grow, offering an eco-friendly option without compromising on the material’s performance.

The developments in PETG and polycarbonate filaments, coupled with the rise of recycled materials, are shaping the future of 3D printing. These trends not only reflect a growing demand for high-performance materials but also highlight the industry’s shift towards more sustainable and eco-conscious practices. As the 3D printing market continues to mature, innovations in materials will play a pivotal role in expanding the range of applications and driving the adoption of additive manufacturing across industries.

Get the complete view on 149 Pages Research Report on 3D Printing Plastics: https://www.marketdigits.com/3d-printing-plastics-market

Frequently Asked Questions about the 3D Printing Plastics Market

How big is the 3D Printing Plastic Market?

The global 3D printing plastics market was valued at approximately USD 3.20 billion in 2024 and is expected to experience substantial growth, with a projected compound annual growth rate (CAGR) of 24.2%. By 2032, the market is estimated to reach USD 17.33 billion. The increasing adoption of 3D printing technology across industries like aerospace, automotive, healthcare, and consumer goods is driving this expansion. The demand for plastic filaments such as PLA, PETG, and polycarbonate continues to rise as more companies integrate additive manufacturing into their production processes.

How Much Does 3D Printed Plastic Cost?

The cost of 3D printed plastic varies depending on the type of material used. For example, PLA, one of the most common materials used in 3D printing, typically costs between $15 and $20 per kilogram. On the other hand, high-performance plastics like polycarbonate or specialized composite filaments are more expensive, ranging from $60 to $120 per kilogram. The price difference is attributed to the material’s properties, such as strength, heat resistance, and durability, which make them ideal for more demanding applications. As the 3D printing market continues to evolve, the cost of printing materials may fluctuate based on demand, availability, and technological advancements.

Where Will 3D Printing Be in 5 Years?

In the next five years, 3D printing is expected to become a mainstream technology in mass production. This growth is driven by the increasing adoption of 3D printing technologies in sectors like manufacturing, automotive, aerospace, and healthcare. 3D printing is likely to play a significant role in the production of customized products, spare parts, and complex components, offering businesses new opportunities for cost savings, design flexibility, and supply chain optimization. Furthermore, advances in materials and printing speeds will make 3D printing more efficient and cost-effective for large-scale production.

Is There Profit in 3D Printing?

Yes, there is potential for profit in the 3D printing industry. With the growing demand for customized products and the ability to produce complex parts on-demand, businesses and individuals can capitalize on various revenue streams. Some of the profitable avenues include offering 3D printing services, selling pre-made 3D prints, creating and selling 3D designs, or even providing educational courses on 3D printing. Profitability in the 3D printing sector depends on factors such as market demand, pricing strategies, the cost of production, and the efficiency of operations. Many entrepreneurs have found success by tapping into niche markets and focusing on creating high-quality, unique products that meet specific customer needs.

Get a Discount on the Premium Research Report on 3D Printing Plastics: https://www.marketdigits.com/request/discount/316

Other Trending Reports

Chitosan Market: https://www.marketdigits.com/chitosan-market-1713352833

USA Amino acid fertilizers Market: https://www.marketdigits.com/usa-amino-acid-fertilizers-market-1714044231

Asia Pacific Conformal Coatings Market: https://www.marketdigits.com/asia-pacific-conformal-coatings-market-1715592398

Europe Conformal Coatings Market: https://www.marketdigits.com/europe-conformal-coatings-market-1715592919

MEA Conformal Coatings Market: https://www.marketdigits.com/mea-conformal-coatings-market-1715593354

North America Conformal Coatings Market: https://www.marketdigits.com/north-america-conformal-coatings-market-1715593887

U.S. Conformal Coatings Market: https://www.marketdigits.com/us-conformal-coatings-market-1715595094

Asia Pacific Wastewater Treatment Market: https://www.marketdigits.com/asia-pacific-wastewater-treatment-market-1715600001

Wastewater Treatment Market: https://www.marketdigits.com/wastewater-treatment-market-1715602774

MEA Wastewater Treatment Market: https://www.marketdigits.com/mea-wastewater-treatment-market-1715603073